Safety Testing

Protect consumers by reducing the risk of accidents or injuries from your products

WHAT IS SAFETY

TESTING?

Electronics safety testing refers to a series of evaluations and assessments conducted to ensure that electronic devices, components, or systems meet the necessary safety standards and regulations. The primary objective of electronics safety testing is to identify and mitigate potential hazards and risks associated with the use of electronic products, thereby ensuring the protection of users, property, and the environment.

WHY IS SAFETY

TESTING

IMPORTANT?

By conducting electronics safety testing, manufacturers can ensure that their products are designed, manufactured, and operated with an emphasis on safety. This helps protect consumers, reduce the risk of accidents or injuries, and build confidence in the reliability and quality of their electronic devices in the market.

GETTING STARTED

with SAFETY

TESTING

Safety testing encompasses various aspects of electronic devices, including electrical safety mechanical safety, and fire safety

It involves a rigorous examination of factors such as insulation grounding protection against electric shock flammability thermal management, and adherence to specific safety standards and regulations

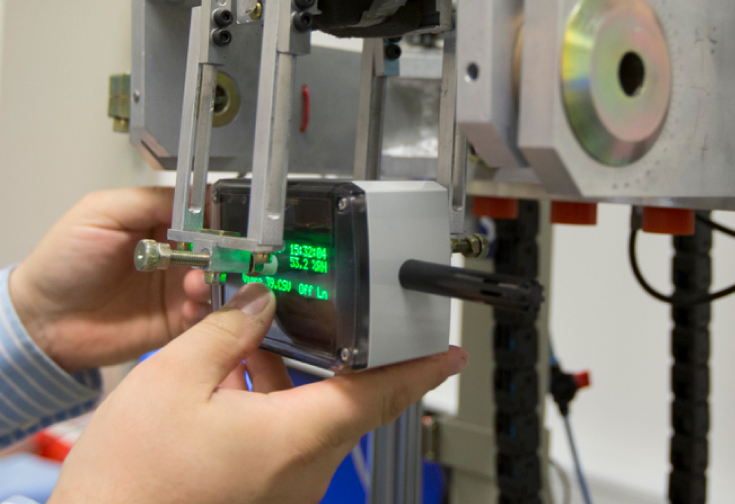

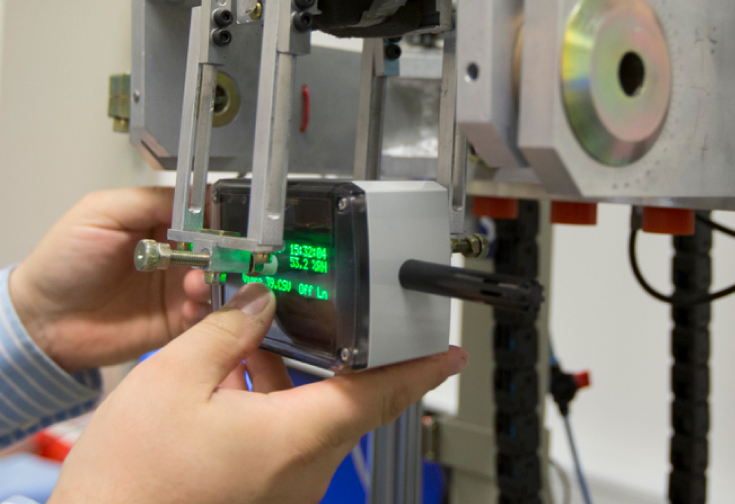

The testing process may involve conducting inspections electrical measurements environmental simulations, and performance evaluations.

It aims to verify that the electronic products comply with applicable safety standards and regulations, such as UL (Underwriters Laboratories) IEC (International Electrotechnical Commission), and national or regional safety requirements.

EXPLORE OUR CUTTING-EDGE

SAFETY TESTING

CAPABILITIES

- High voltage: up to 5 kV AC & 6 kV DC

- Earth continuity: up to 36 A

- Encapsulation strength

- Insulation resistance: 0-1000 MΩ